6 Good 3d Printing Troubleshooting Guides" Fabbaloo

페이지 정보

본문

3D printing capacities can be particularly important for makers that require difficult-to-find more info components and devices for maturing machinery, particularly at legacy manufacturing plants. 3D published building models for bronze casting The visually impaired can touch as well as feel the bronze models to get a thorough impact of the forms and also surface areas of the structures. Art room from the 3D printer Engineers have actually already been utilizing 3D printing innovation for creating true-to-scale models for a number of years. Whether in layout, individualization, lightweight building and construction, bionics or in iterative item development, additive manufacturing pushes the limits of what has been feasible up until now.

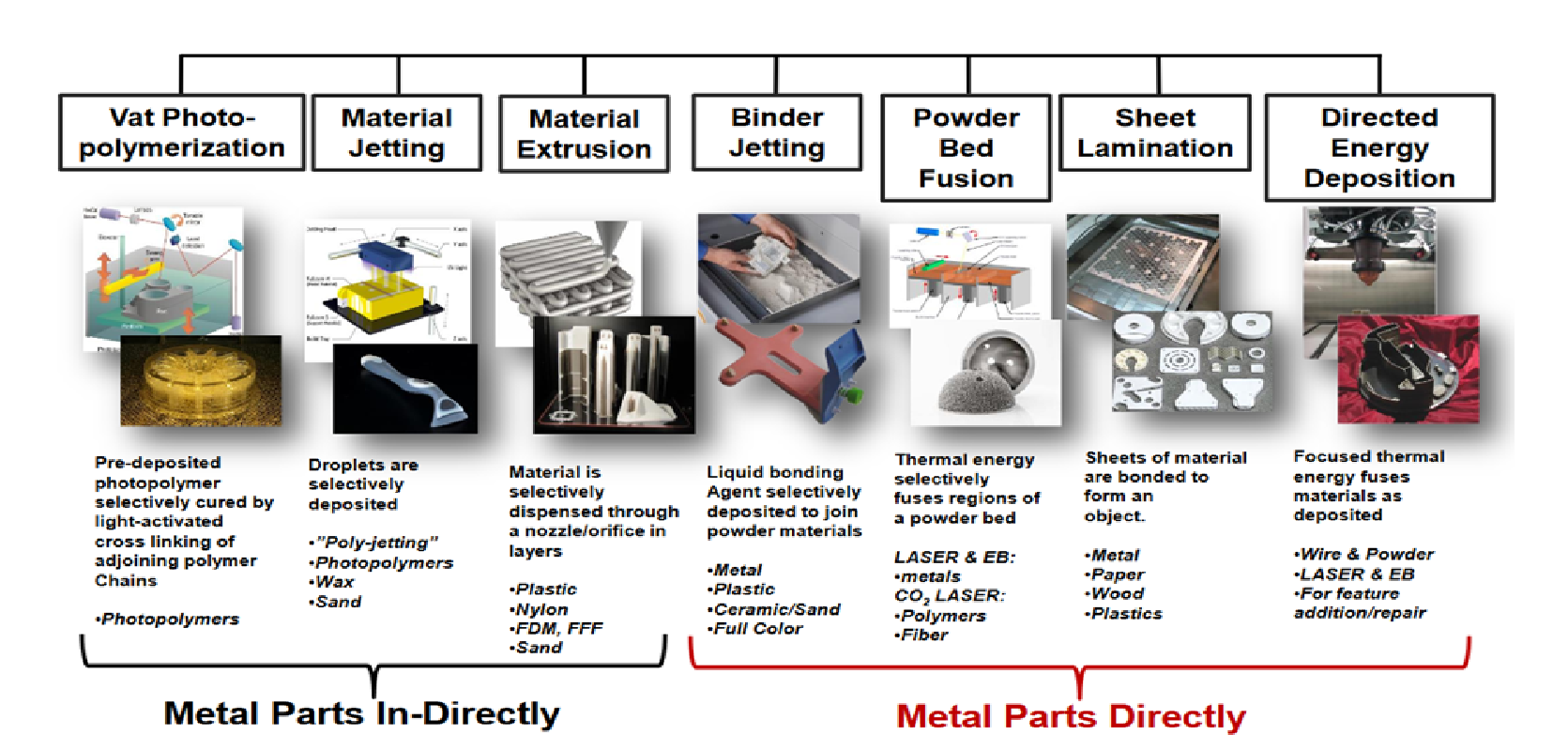

3D printing capacities can be particularly important for makers that require difficult-to-find more info components and devices for maturing machinery, particularly at legacy manufacturing plants. 3D published building models for bronze casting The visually impaired can touch as well as feel the bronze models to get a thorough impact of the forms and also surface areas of the structures. Art room from the 3D printer Engineers have actually already been utilizing 3D printing innovation for creating true-to-scale models for a number of years. Whether in layout, individualization, lightweight building and construction, bionics or in iterative item development, additive manufacturing pushes the limits of what has been feasible up until now.You can not be connected to any kind of technology industry and not hear about all the benefits offered by 3D Printing Expert Insights printing. The quantity of versatile applications supplied by 3D printing has actually been a leading consider its well-earned appeal. Make effective models without any headache, contact RapidDirect for costs 3D printing services at the very best price. Just as its name suggests, sheet lamination is a method that piles exceptionally thin sheets of steel over each other to generate a 3D item. However, this process is rather incorrect but generates incredibly quick as well as affordable results.

Since then, we've come a long method, from human-made to human-and-machine-made. Currently, concerning three-quarters of survey individuals are doing their additive production in-house. It does appear that firms are branching off in their pre- and also post-processing techniques. In 2019, a little over half of respondents stated that they were making use of machining; now, virtually three-quarters of participant are, dismissing polishing as the most preferred option. Thinking about that all handling methods enhanced significantly, it may be that firms are experiencing some growing discomforts as well as these difficulties will certainly lessen as firms continue to make this a top priority.

Polycarbonate (PC) is an advanced design polycarbonate with outstanding mechanical residential properties and is the strongest 3D printer filament. It has high strength and a glass change temperature of 150 °& #xb 0; C, making it ideal for high-temperature applications.

Solidifying includes heating the component to a specific temperature over its top important temperature level and also holding it there for High-Quality 3D Prototyping a defined time. The part is after that rapidly appeased, transforming its microstructure into a hard as well as breakable phase called martensite. After service annealing, the component undergoes an aging process, in which it is heated up to a lower temperature as well as held for a fixed time. This controlled heat treatment permits the precipitates to develop in a regulated manner, enhancing the mechanical residential properties of the product. To get rid of dissolvable assistances, the printed part is submerged in a container full of the suitable solvent or merely run under a faucet. The dissolution procedure can take numerous hours or even days, depending on the size and also complexity of the support frameworks.

The best method to adjust your retraction settings is to publish a retraction tower that is made up of several blocks. Adjusting your retraction length and also speed setups can aid you prevent a ton of troubles when publishing with PLA, such as oozing and stringing. Increasing your wall surface or covering thickness is just one of the most effective means of making solid 3D Modeling and Printing Guide prints. If you seek an useful component however do not want to utilize a difficult filament like Nylon or Polycarbonate, this is the way to go. PLA isn't one of the most preferred 3D printer filament for no great factor.

Q: Can 3d Printers Be Used By Younger Pupils, Such As Kindergarteners?

Rectangular infills can attain 100% infill density because of their grid of parallel and vertical extrusions. Like the triangular infill, it likewise has a high print speed due to the print head's straight-line motion. Utilizing a triangular infill also boosts print rate because of the straight-line activity of the printhead.

An additional unusual reason is the nozzle temperature level, but that will hold true only if you utilize inexpensive, inappropriate or obsolete filaments. The latter will once more lead to a path of material as a result of the raised recurring heat of the nozzle. Prior to printing, make sure to get rid of any kind of excess material or cloggings left in the nozzle, otherwise it won't have the ability to correctly extrude the material. Even the smallest obstruction will lead to noticeable misprints as well as result in a crude-looking product. Adhering to those solution, it's extremely preferable to repair non-manifold geometry issues of the design before posting it into the slicer software.

Summary Of Solutions: Published Designs Don't Stay With Publish Plate

You might additionally run into some odd misprinted locations that certainly weren't on the sneak peek. For example, the Ultimaker 2 has eight wheels attached to the main straight rods. It is a straightforward fix, yet occasionally the grub screws are not quickly available. In the beginning, you ought to determine which sheave causes the problem and then try to get accessibility. The outcome looks on the whole good, yet you can see the summary of the infill with the wall surfaces from the outside. You will additionally see if the nozzle is also close or expensive.

- 이전글prometrium 100 mg auf ärztliche Verschreibung erhältlich utrogestan ohne ärztliche Verschreibung kaufen 23.11.26

- 다음글The Most Significant Issue With Must See Girlfriend In Pattaya Agencies Bangkok Thailand And How You Can Fix It 23.11.26

댓글목록

등록된 댓글이 없습니다.

회사소개

회사소개